FAQs

Mid-2014 should be about right but a date is hard to pin down. The more we get into the project the more complex it becomes! We’re pushing for a level of accuracy and detail that hasn’t been achieved before in a kit of this type. Progress is steady and I’m confident we can produce an outstanding result. It will just take a little longer than initially expected and it will be worth the wait!

This has not been determined yet. It depends on production costs. For example, we are now looking to include appropriate pre-tooled parts and hardware for armatures and connectors to make it easy to assemble. please budget for around US$399.

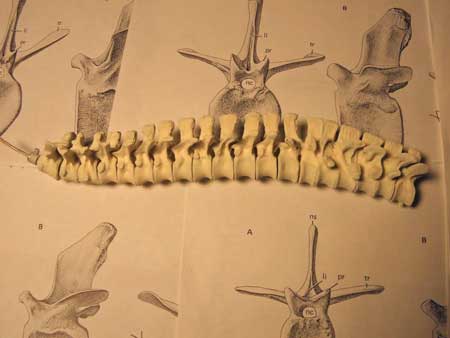

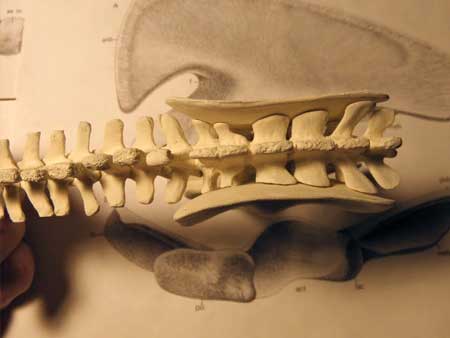

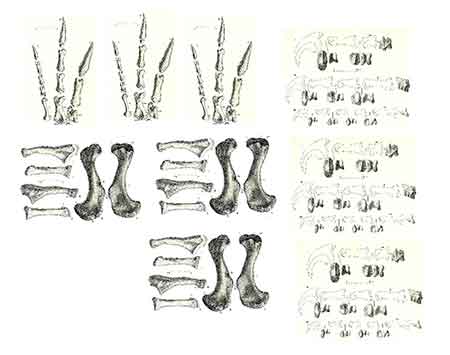

Furthermore, having separate bones, particularly all the vertebrae, allows the skeleton to be posed any way you like. The entire skeleton will conform to any pose you can imagine within the animal's natural range of motion. Creating a great composition is half the fun of a project like this!

The kits are made in the USA and ship from there. Exact postage will depend on your location and the final size and weight of the kit, which is unknown at this time.

Progress Photos

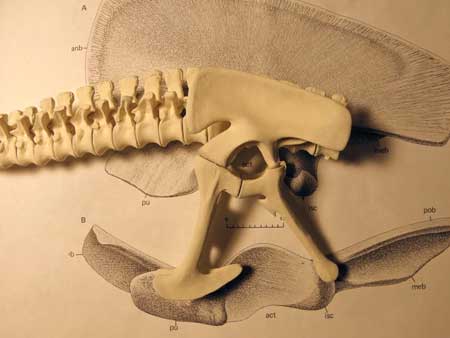

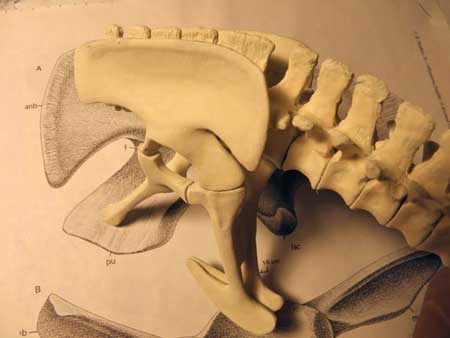

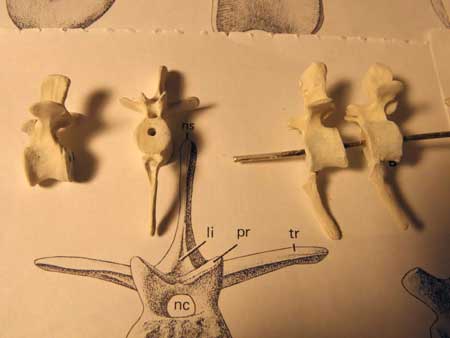

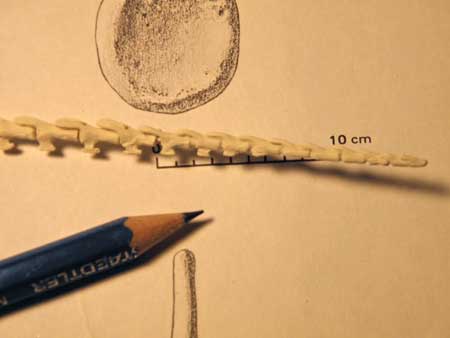

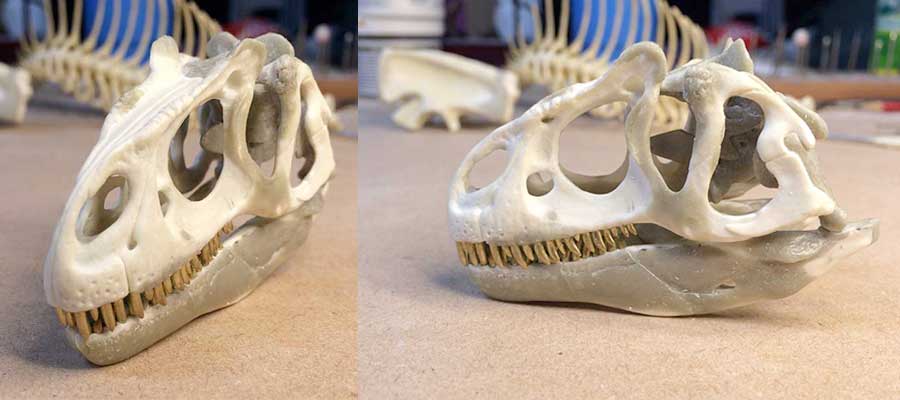

Jan 2014 progress photos. Still rough in places but getting there...

December 2013: Master skull. Mixed media , in progress (resin, epoxy putty, brass teeth). 4 parts: separate mandible halves, separate braincase (below).

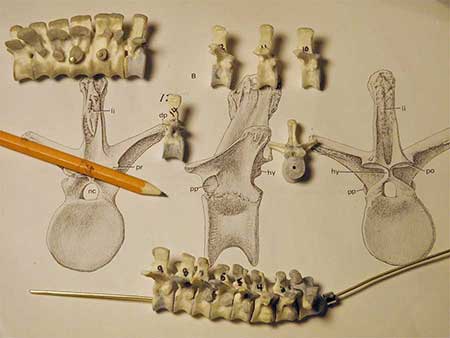

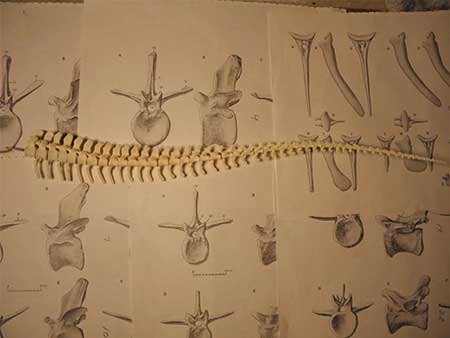

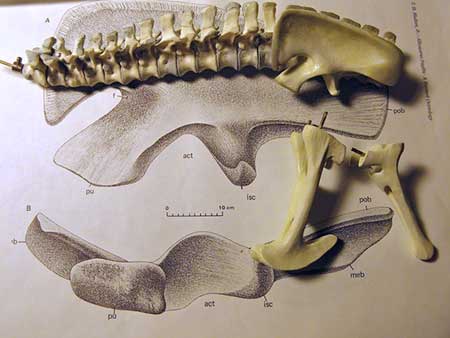

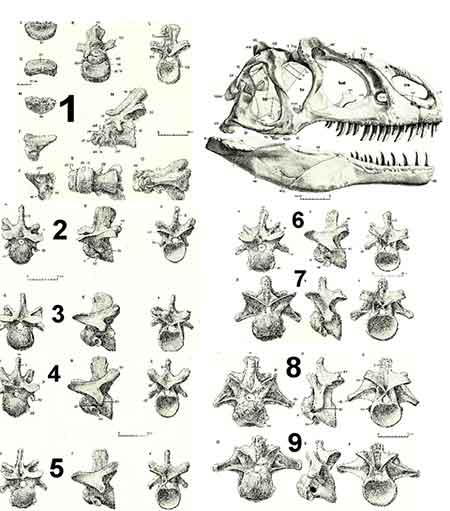

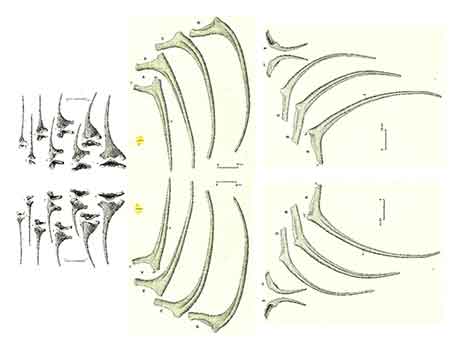

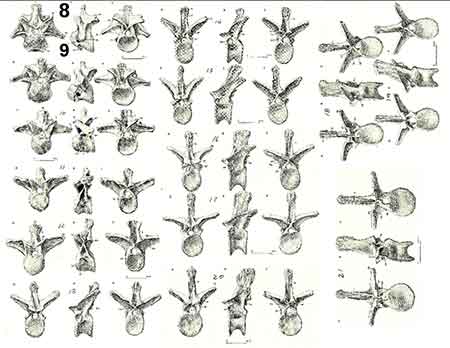

September-November 2013: First step was to scale all the drawings, print them, cut them out, stiffen them with glue and sculpt a basic shape part over each cutout to correct scale. This is much the same process as used by Shigeru Yamazaki. Here are pics of a few of the template sheets that were used.

Resulting rough parts were assembled into a Scaffold Cast and this was recast in resin. The Scaffold Cast model was taken apart and each bone was carefully detailed to create a Master model used to create the final production parts.